One of Spectrum Control’s key engineering capabilities is our ability to deliver customized microelectronics based on customers’ design and performance requirements. Our manufacturing expertise in design/build-to-specification and build-to-print make us a leading manufacturer for multi-chip modules (MCMs) and MMIC-based integrated microwave assemblies (IMAs).

Our in-house, clean-room manufacturing, along with our relationship with strategic partners for MMICs, means customers can turn to us to deliver on the demanding RF performance requirements for key markets such as wireless communications, electronic warfare, military aircraft, and naval carriers.

Whether you need support for build-to-print MMIC-based IMA manufacturing or a full custom design to specification, we can support your needs. We can build using our own products, including RF amplifiers, surface mount attenuators, microelectronics and other products, and incorporate products from the customer’s product vendor list.

Our proprietary process of glass microwave integrated circuit (GMIC) focuses on the niche market that is between substrates and custom MMICs. GMIC offers significant advantages as an enabling technology for the low cost production of mmWave circuits, where the application of a custom MMIC does not fit the product cost model. The proprietary GMIC is a mature process, which has been in production for more than 15 years.

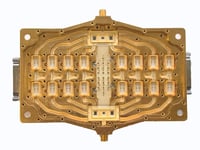

MCMs are designed in a variety of forms, depending on the type and complexity. Also known as integrated circuits (IC), MCMs are an electronic package that has multiple ICs assembled on a single device. It works as a single component, capable of handling an entire function. Our capabilities for designing and building an MCM include fully custom mixed-signal microelectronics solutions, build-to-print microelectronics assemblies, and Class K compliance.

MCMs are designed in a variety of forms, depending on the type and complexity. Also known as integrated circuits (IC), MCMs are an electronic package that has multiple ICs assembled on a single device. It works as a single component, capable of handling an entire function. Our capabilities for designing and building an MCM include fully custom mixed-signal microelectronics solutions, build-to-print microelectronics assemblies, and Class K compliance.

MCMs can be manufactured with substrate technology, die attach, bonding technology, and encapsulation technology. These designs allow for miniaturization, reduced complexity, improved reliability, and better performance. They commonly are used in power amplifiers, wireless modules, space avionics, and single-module computers. Offering a more than 30 percent packaging efficiency, MCMs offer a variety of advantages that include reduced size, lower power supply inductance, less crosstalk, lower off-chip driver power, and improved reliability on a simplified design.

MCMs are extensions of hybrid microcircuits that offer exceptional opportunities to implement high-performance and high-capacity signal processing. They can consist of a number of MMICs or a number of assemblies, and they can be stand-alone or part of an integrated microwave assembly (IMA).

Monolithic microwave Integrated Circuits (MMICs) are used for designing very high frequency and high-powered electronics circuits, while offering system benefits with cost, reliability, reproduction, and control of circuit parameters. Built as integrated circuits, MMICs are designed for microwave frequencies that, sometimes, are as high as millimeter-wave frequencies for mm-MMICs.

Monolithic microwave Integrated Circuits (MMICs) are used for designing very high frequency and high-powered electronics circuits, while offering system benefits with cost, reliability, reproduction, and control of circuit parameters. Built as integrated circuits, MMICs are designed for microwave frequencies that, sometimes, are as high as millimeter-wave frequencies for mm-MMICs.

Spectrum Control’s capabilities include our in-house UK and US design teams and state-of-the-art design tools. They ensure that standard and customized MMIC devices achieve the right performance for critical specifications such as RF, electromagnetic, mechanical, thermal, and stress analysis. MMICs are highly dense component packages that utilize and process microwave signals internally, meaning they are key for applications looking for SWaP-C optimization. MMICs perform a variety of functions such as microwave mixing, power amplification, low-noise amplification, and high-frequency switching.

MMICs are made up of a number of different high-frequency components on the same chip, delivered in a semiconductor die form or on a surface-mount-technology (SMT) package that is mounted on a printed circuit board. These devices can be a passive component such as a filter, or an active component such as an amplifier.

Originally fabricated solely on gallium-arsenide (GaAs) semiconductor wafers, MMICs now are based on a wide range of semiconductor materials. These include silicon (Si), indium phosphide (InP), silicon germanium (SiGe), and, increasingly, gallium nitride (GaN) for operating at high voltages and high-power levels at microwave frequencies, as a basis for microwave amplification and for transmitter and transceiver circuits.