Circular connectors offer the capability to transmit power and electrical signals in multi-pin designs. They are easily installed and removed. Because of their cylindrical structure, they are sealed to provide the toughest performance in the harshest of applications. They have outstanding mechanical sturdiness and a higher strength-to-weight performance critical for high shock and vibration environments. EMI Filter Circular Connectors strip unwanted electromagnetic interference (EMI) or transient voltages from signal lines by incorporating ceramic capacitors. This type of connector provides effective EMI filtering, reducing the amount of real estate required within a product enclosure.

An EMI filtered circular connector is most frequently used in military and aerospace applications, including communications, missile systems, military vehicles, and engine controls. Custom connectors are offered in military standards: MIL-DTL-55116, -83723, -24308, -26482, and -5015. In addition, connectors for transient survival that meet criteria for RTCA/DO-160, level 4 (1,500 voltage transient) are available.

|

|

|

Factor |

Board Mounted |

In Connector |

|

Size |

Takes Up Board Space | No Board Space Required |

| Weight | Comparable since the board will require additional filtering component on the PCBA. | Comparable; will replace an existing unfiltered connector as well as PCB space and on-board capacitors and/or filters. |

| Installation Time | Board Population | Free - connectors are necessary |

| Board Space | Yes | Saves board space |

| Component Cost | Lower Cost | Higher Cost |

| Filtering Level | Lower Protection | Higher Protection |

Read more about Spectrum Control’s successful projects using EMI filter circular connectors to protect system designs from EMI.

|

Glass-sealed for Aircraft Fuel Tank Sensors Rugged connectors with hermetic seals and steel shells to protect the circuits of these sensors from EMI caused by the plane's avionics. |

|

|

Composite Shells for Aircraft Motor Controls Replace traditional metal connector shells for substantial weight reduction while maintaining the form, fit, and function of the original connector shell. |

|

|

Transient Survival for Aircraft Lightning Protection Address strict safety requirements for protection in modern aircraft to maintain critical electronic equipment during hazardous transient conditions. |

|

|

EMI filter connectors safeguard automatic robotic control systems from RF interference and ensure the functions continue to operate accurately and safely. |

Download the line card to see our complete line of products.

|

Transient Survival Connectors: Meet standards for RTCA/DO-160 Level 4 lightning requirements. |

|

|

|

Black Nickel Zinc Connectors: RoHS-compliant, cost-effective, and sustainable plating alternative to Cadmium. | |

| Composite Shell Connectors: Designed to replace traditional metal connector shells for substantial weight reduction. |

|

|

|

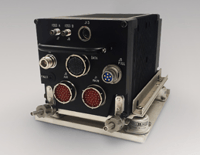

Power Connectors: Power filter in a circular connector package with integrated common and differential mode EMI filtering. |

Spectrum Control has been a leader in providing application-specific EMI filtered connector solutions since its founding in 1968. We offer the industry’s most extensive line of connectors designed for high-reliability or demanding environmental applications. It is rare to find an off-the-shelf connector that completely satisfies environmental, mechanical, and electrical requirements. Our engineering team is ready to modify one of these existing designs or start with a "clean sheet" to ensure your connector satisfies these requirements. In addition, we can accommodate your quick-turn schedule for prototyping by adding either planar or tubular capacitor filtering to the rear of a standard connector. Contact our sales team.

Spectrum Control's circular connectors are fully vertically integrated. Our USA facility manufactures components, including ceramic capacitors and shells. Spectrum Control has recently expanded the production capabilities in this facility with state-of-the-are equipment providing customers with high-quality parts with the industry’s shortest lead times.